Exploring the Different Types of Welding Joints

When it comes to welding, the type of joint you choose is crucial for the strength and durability of the finished product. Each welding joint has its own applications, advantages, and challenges. In this blog, we'll dive into the various types of welding joints, explore which one is considered the strongest, and discuss welded joints in pipes

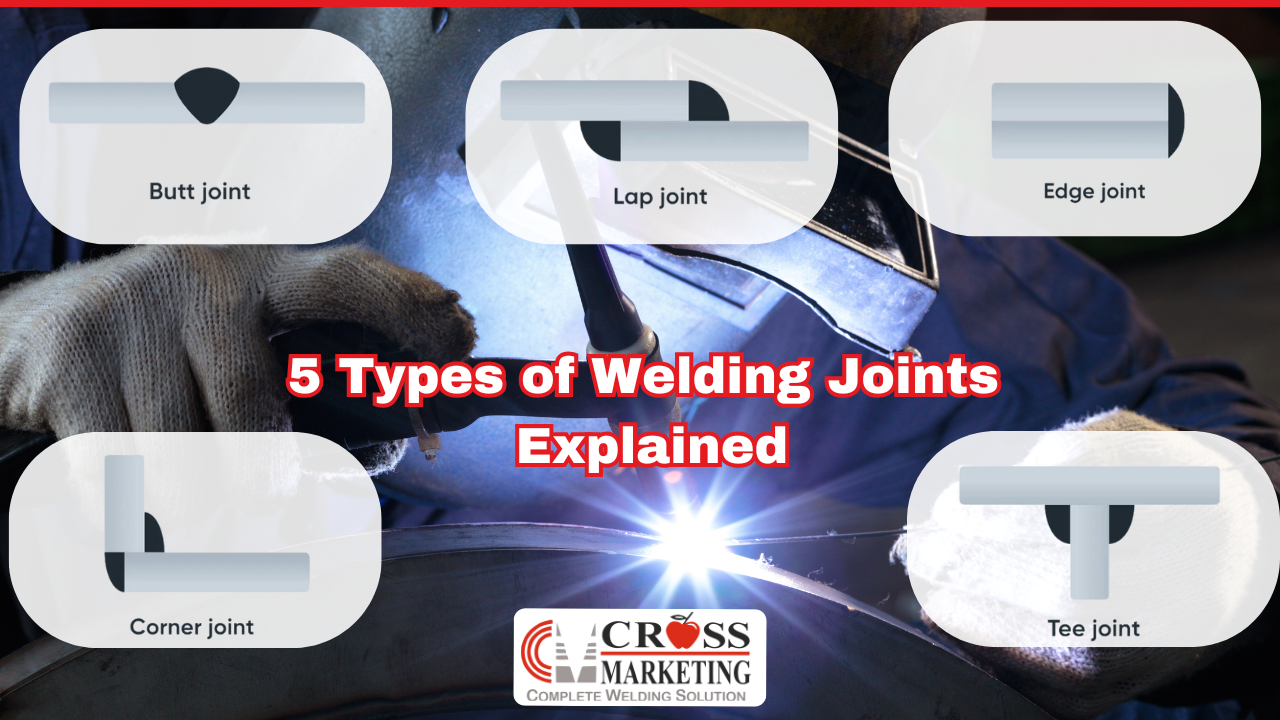

Types of Welding Joints

-

Butt Joint

- Description: Two pieces of metal are placed edge-to-edge in the same plane.

- Applications: Commonly used in manufacturing structures, pipelines, and frames.

- Advantages: Simple to prepare and requires minimal filler material.

-

Corner Joint

- Description: The edges of two metal pieces are joined to form a corner.

- Applications: Often used in the construction of boxes, frames, and other right-angle structures.

- Advantages: Provides good stability and strength at the corner.

-

Lap Joint

- Description: Two overlapping pieces of metal are joined.

- Applications: Used in sheet metal fabrication, automotive bodies, and structures requiring reinforcement.

- Advantages: Offers a large surface area for welding, making it strong and resistant to shear forces.

-

T-Joint

- Description: One piece of metal is perpendicular to the other, forming a "T" shape.

- Applications: Used in various structural applications like brackets, supports, and frames.

- Advantages: Easy to weld and provides a strong connection.

-

Edge Joint

- Description: The edges of two or more pieces are placed together, often used with thin sheets.

- Applications: Common in sheet metal work and the fabrication of tanks and containers.

- Advantages: Suitable for joining thin materials with minimal preparation.

What is the Strongest Weld Joint?

Among the different types of welding joints, the butt joint is often considered the strongest, especially when properly executed with full penetration. This is because the weld can be made through the full thickness of the material, creating a robust and seamless connection. In critical applications, a double-sided butt joint can be used to enhance strength and ensure complete penetration.

What is a Welded Joint in Pipe?

Welded joints in pipes are crucial for creating a continuous and leak-proof connection in piping systems. The most common types of welded joints in pipes include:

-

Butt Welded Joint

- Description: Two pipe ends are aligned and welded edge-to-edge. This joint is commonly used for high-pressure applications.

- Advantages: Provides a smooth inner surface, reducing turbulence and allowing for efficient flow.

-

Socket Welded Joint

- Description: One pipe end is inserted into a recessed area of the other pipe or fitting, then welded around the outer circumference.

- Advantages: Ideal for smaller diameter pipes and applications where space is limited.

-

Fillet Welded Joint

- Description: Used when pipes are connected at an angle, such as in T-joints or corner joints.

- Advantages: Provides strong joints for complex geometries and directional changes in piping systems.

Conclusion

Understanding the different types of welding joints and their applications is essential for selecting the right method for your project. The butt joint stands out as the strongest type, especially when full penetration is achieved. In piping systems, butt welded, socket welded, and fillet welded joints each offer unique advantages depending on the application. By choosing the appropriate welding joint, you can ensure the structural integrity and longevity of your welded structures.

For more insights into welding techniques and best practices, stay tuned to our blog and explore our comprehensive resources on welding and fabrication.