Description

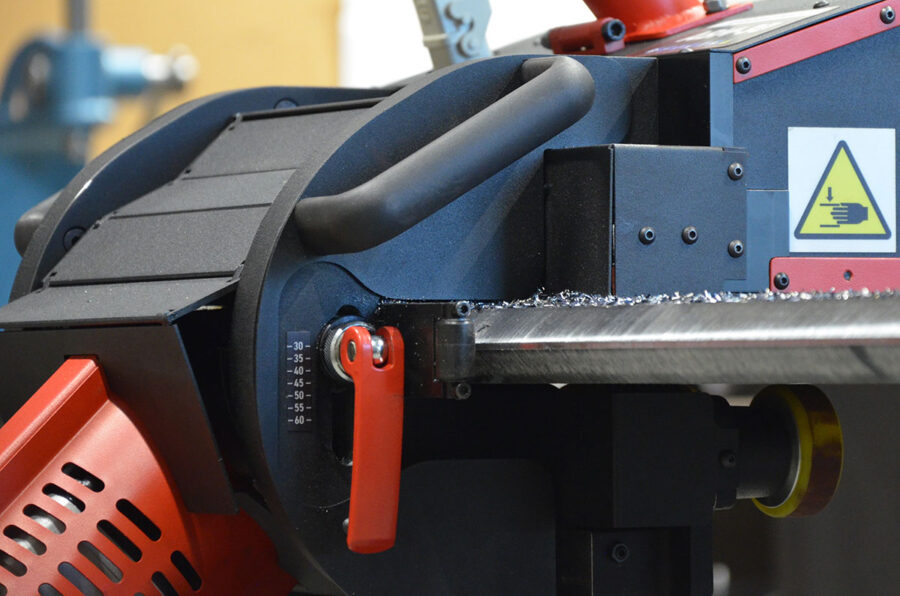

The ABM-30 portable beveling machine performs auto-feed beveling on steel plates on the top, face, and bottom edges. The beveller needs no track to move along the steel plate to produce accurate high-quality double-side bevels without thermal distortion or creation of heat affected zone on plate thickness range 8-60 mm. The ABM-30 features an infinitely adjustable bevel angle between – 70 and + 70 degrees and is capable of producing bevels up to 30 mm wide. It also allows for facing in both directions, with the milling head depth of 1 mm.

- 4-wheel drive eliminates the need for a guide track

- self-propelled machine for consistent bevel geometry from edge to edge

- control panel indicates the current work mode and gives safety and diagnostic information

- capable of producing bevels up to 30 mm wide

- infinite bevel angle adjustment from -70 to +70 degrees is quick and user-friendly

- produces double-side bevels without having to flip the plate, enhancing safety and reducing material handling time and expense

- feedback-controlled overload system to prevent motor damage

- semi-automatic drive stop at the plate end

Specification

| Voltage | 1~ 200-240 V, 50/60 Hz 1~ 110-120 V, 50/60 Hz |

| Power | 2200 W |

| Spindle rotational speed (without load) | 1800-5850 rpm |

| Feed speed | 0-2 m/min (0–6.5 ft/min) |

| Bevel angle | From -70° to 70° |

| Maximum bevel width | 30 mm (1.18”) |

| Sheet thickness | 8-60 mm (0.3–2.3”) |

| Required ambient temperature | 5-40°C |

| Weight | 43 kg (94.8 lbs) |