Description

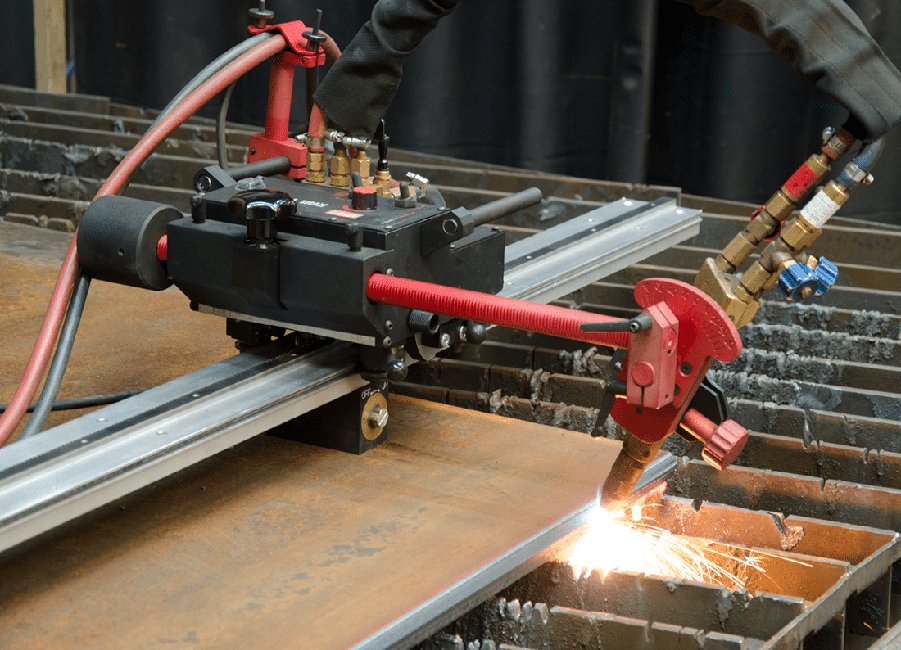

The Rail Tug is a basic tractor designed for the mechanization of welding and thermal cutting processes. The tractor can move along ring, hi-flex, semi-flexible or rigid tracks on flat, curved and round surfaces. The tracks can be fixed to both ferromagnetic and non-ferromagnetic materials thanks to various magnetic or vacuum units. Featuring a rack and pinion drive system with electronic speed control, Rail Tug creates weld bead geometry which is exact to your specifications, reducing costly over welding and decreasing filler metal usage.

| Voltage | 1~ 115–230 V, 50–60 Hz |

| Power | 66 W |

| Welding position (according to EN ISO 6947 and AWS/ASME) | PA / 1F / 1G PB / 2F PC / 2G PD / 4F PE / 4G PG / 3F (contact your dealer) |

| Fixing on pipes and round workpieces - Ring tracks | PA / 1F / 1G PB / 2F PC / 2G PD / 4F PE / 4G PG / 3F (contact your dealer) |

| Fixing on pipes and round workpieces - Hi-flex tracks | PA / 1F / 1G PB / 2F PC / 2G PD / 4F PE / 4G PG / 3F (contact your dealer) |

| Torch type | MIG/MAG, SAW, Plasma, Oxy-fuel |

| Fixing on pipes and round workpieces - Semi‑flexible track | Minimum curvature radius of 5 m (16 ft) |

| Torch diameter -MIG/MAG | 16–22 mm (0.63–0.87’’) up to 35 mm (1.38”) option |

| Torch diameter SAW, Plasma | 16–22 mm (0.63–0.87’’) up to 35 mm (1.38”) option |

| Torch diameter Oxy-fuel | 16–22 mm (0.63–0.87’’) up to 35 mm (1.38”) option |

| Horizontal pulling force | 300 N |

| Vertical pulling force | 200 N |

| Horizontal speed | 10–200 cm/min (4–80 in/min) |

| Vertical speed | 10–200 cm/min (4–80 in/min) |

| Weight | 10 kg (22 lbs) |

| Product Code (115–230 V, 50–60 Hz, plug EU) | WOZ-0570-10-20-00-0 |